Tank setup update

Moderator: LoachForumModerators

- Keith Wolcott

- Posts: 720

- Joined: Sun Mar 04, 2007 1:49 pm

- Location: Charleston, Illinois USA

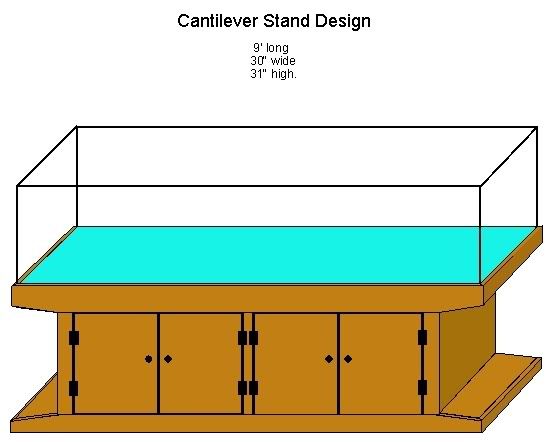

I think the cantilever design will look incredibly stunning when it's finished. I'm glad you have an engineer helping you with this, otherwise I'd be a little skeptical.

The solid 2x4 and plywood top looks like it should be strong enough for a cantilever design.

My only question is about the deflection calculations. I don't understand how the cantelever ends are calculated to deflect up if this is a glass tank where the load would be bearing around the perimeter of the stand. If the stand had a uniform load, like an acrylic tank would give it, then I would understand the deflection calculations better.

Great design nevertheless.

The solid 2x4 and plywood top looks like it should be strong enough for a cantilever design.

My only question is about the deflection calculations. I don't understand how the cantelever ends are calculated to deflect up if this is a glass tank where the load would be bearing around the perimeter of the stand. If the stand had a uniform load, like an acrylic tank would give it, then I would understand the deflection calculations better.

Great design nevertheless.

- Keith Wolcott

- Posts: 720

- Joined: Sun Mar 04, 2007 1:49 pm

- Location: Charleston, Illinois USA

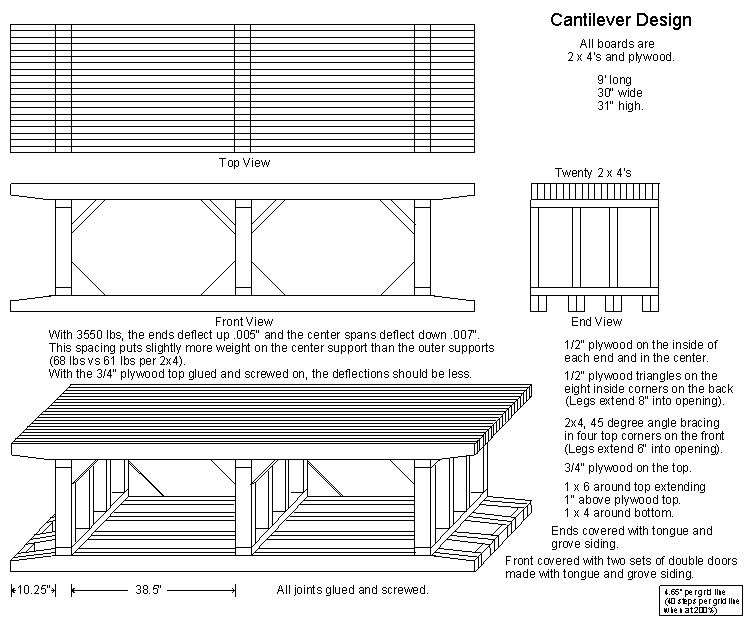

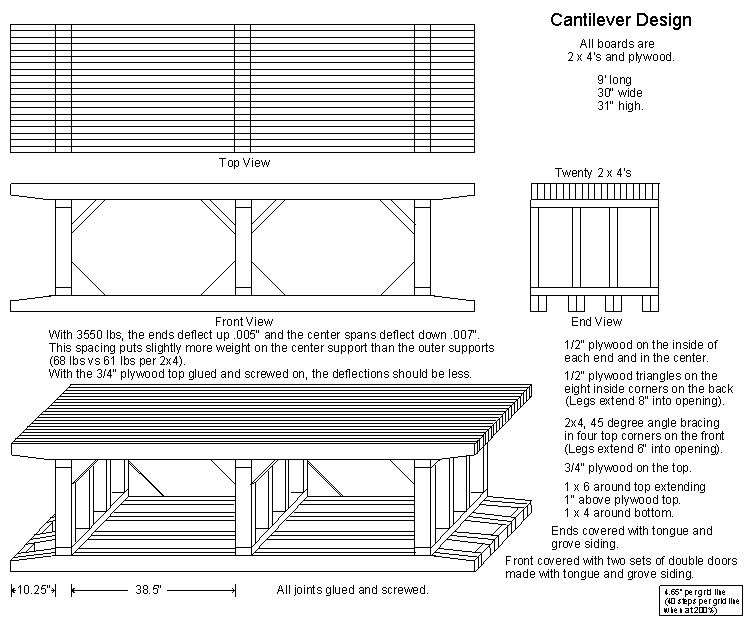

chefkeith- There is more load around the edge, but only the difference between the weight of the side glass and the weight of water and also the top glass bracing. This is rather small (several hundred lbs) compared to the entire weight of the filled tank of about 3550 lbs. Thus, the weight is pretty much evenly distributed. You might not know that this tank has no frame. That is, the glass bottom sits directly on the stand. With 3/4 inch foam underneath, even in the case that there is a plastic frame, it will sink into the foam and the weight will be pretty much evenly distributed.

Also, the deflections are computed when the weight is evenly distributed on just the 2x4's. The plywood will give less deflection and the glass is also very strong and will give less deflection yet. The deflections are so small that imperfections and unevenness of the top will most likely be larger and more of a problem than the deflections from the weight.

Also, since the weight distribution is not 100% evenly distributed and there is a little more around the outside, is one reason why we did not set the outside supports at the balance point and we moved them out about a 1.5 inches.

Keep being skeptical! I appreciate questions, since it is always easy to make mistakes or overlook something and I do want to get this right.

Also, the deflections are computed when the weight is evenly distributed on just the 2x4's. The plywood will give less deflection and the glass is also very strong and will give less deflection yet. The deflections are so small that imperfections and unevenness of the top will most likely be larger and more of a problem than the deflections from the weight.

Also, since the weight distribution is not 100% evenly distributed and there is a little more around the outside, is one reason why we did not set the outside supports at the balance point and we moved them out about a 1.5 inches.

Keep being skeptical! I appreciate questions, since it is always easy to make mistakes or overlook something and I do want to get this right.

- Keith Wolcott

- Posts: 720

- Joined: Sun Mar 04, 2007 1:49 pm

- Location: Charleston, Illinois USA

I thought seriously about building it myself, but decided to have it built. Aquariums For You is building it. It is expensive, but people that I talked to seemed to be happy with their work. It will have the low iron, clear glass on the front and the left end. The edges will be ground and polished. Extra glass bracing is put in around the perimeter of the base and Euro bracing is put around the top (2" wide). There will be 4 openings on the top. It will be the same dimensions and construction as the aquarium pictured below, except mine is 9 feet long instead of 8.

- crazy loaches

- Posts: 708

- Joined: Thu Sep 28, 2006 7:12 am

- Location: Gahanna, Ohio

- Contact:

- Keith Wolcott

- Posts: 720

- Joined: Sun Mar 04, 2007 1:49 pm

- Location: Charleston, Illinois USA

- Graeme Robson

- Posts: 9096

- Joined: Wed Dec 28, 2005 4:34 am

- Location: Peterborough, UK

- Contact:

- Keith Wolcott

- Posts: 720

- Joined: Sun Mar 04, 2007 1:49 pm

- Location: Charleston, Illinois USA

Great job with the blueprints and drawings. I don't think I've ever done a project without drawing it up first. I think that's half the fun of such a project. So, are you done building the stand yet?

I'm hoping you don't have any difficulties making the top flat, since you are using 20- 2x4's on edge. I've always had a difficult time keeping 2x4's straight. The longer they sit, the more they warp. Usually it's easy to straighten them out with clamps and screwing them down, but with a cantelever stand design there will be nothing to clamp/screw the ends down to. If the 2x4's stay straight then you should have no problems. That's what I'm hoping for.

I'm hoping you don't have any difficulties making the top flat, since you are using 20- 2x4's on edge. I've always had a difficult time keeping 2x4's straight. The longer they sit, the more they warp. Usually it's easy to straighten them out with clamps and screwing them down, but with a cantelever stand design there will be nothing to clamp/screw the ends down to. If the 2x4's stay straight then you should have no problems. That's what I'm hoping for.

- Keith Wolcott

- Posts: 720

- Joined: Sun Mar 04, 2007 1:49 pm

- Location: Charleston, Illinois USA

Thanks Dutch and Shari.

chefkeith- I have not had much time to work on it yet and what little I have done has been slow. When I bought the 2x4's, I picked the best 34 out of about 150 at Home Depot. Now I have chosen the best 20 out of the 34 for the top and have them cut to length. Next is beveling the ends. I did not show it on the last drawing of the structure, but I think I will bevel the ends to give a more aesthetic look. See

One problem with doing this is that I don't have accurate data on how this affects the strength and the deflections. But I think that it will be ok. This effect can also be achieved without beveling the 2x4's by making the facade on the front top and bottom a little wider and just beveling it, but I give up a little height on the entry to the compartments inside and I don't like the look of it quite as much.

If I bevel the 2x4's, counting the bottom, there are 56 ends to bevel. Thus, it is worth the time to make a jig to fit on my table saw that will make it easy to do them quickly and accurately. That's what I am working on now. I'll show pictures when I get something.

You are right about the problems of getting a level surface. I have spent some time thinking about how to glue the 2x4's together to minimize warp. For sideways warp, I am matching 2x4's that warp one way with 2x4's that warp the other way. I have them laid out on saw horses that have been leveled so that I can easily sight along the surface and see how it is warped and I can also put a level on it to see how it is warped. As I glue them together, I will be monitoring how it goes and hopefully minimize warping. It would be very easy to end up with an unacceptable surface, so I will have to work carefully.

I also need some warmer weather. The last two days it was down to the low single digits and my attached garage was only down to 30 degees, but that feels cold after a bit.

chefkeith- I have not had much time to work on it yet and what little I have done has been slow. When I bought the 2x4's, I picked the best 34 out of about 150 at Home Depot. Now I have chosen the best 20 out of the 34 for the top and have them cut to length. Next is beveling the ends. I did not show it on the last drawing of the structure, but I think I will bevel the ends to give a more aesthetic look. See

One problem with doing this is that I don't have accurate data on how this affects the strength and the deflections. But I think that it will be ok. This effect can also be achieved without beveling the 2x4's by making the facade on the front top and bottom a little wider and just beveling it, but I give up a little height on the entry to the compartments inside and I don't like the look of it quite as much.

If I bevel the 2x4's, counting the bottom, there are 56 ends to bevel. Thus, it is worth the time to make a jig to fit on my table saw that will make it easy to do them quickly and accurately. That's what I am working on now. I'll show pictures when I get something.

You are right about the problems of getting a level surface. I have spent some time thinking about how to glue the 2x4's together to minimize warp. For sideways warp, I am matching 2x4's that warp one way with 2x4's that warp the other way. I have them laid out on saw horses that have been leveled so that I can easily sight along the surface and see how it is warped and I can also put a level on it to see how it is warped. As I glue them together, I will be monitoring how it goes and hopefully minimize warping. It would be very easy to end up with an unacceptable surface, so I will have to work carefully.

I also need some warmer weather. The last two days it was down to the low single digits and my attached garage was only down to 30 degees, but that feels cold after a bit.

- crazy loaches

- Posts: 708

- Joined: Thu Sep 28, 2006 7:12 am

- Location: Gahanna, Ohio

- Contact:

Looks great so far (wow thats a lot of work using the cantilever design and beveling  ).

).

Weather is a problem for me too... I havent been able to finish my stand end panels or start on my canopy since I end up doing most of my work in the driveway... my garage is rather full of stuff, and to difficult to work on large projects in it. One of these days I'll clean it out and organize it... probably when we sell the house .

.

Weather is a problem for me too... I havent been able to finish my stand end panels or start on my canopy since I end up doing most of my work in the driveway... my garage is rather full of stuff, and to difficult to work on large projects in it. One of these days I'll clean it out and organize it... probably when we sell the house

Who is online

Users browsing this forum: Google [Bot] and 85 guests